The last part went over power for a model railroad. This part goes over laying track for the railroad. Track is the one of the most important things for a railroad, it delivers the electricity to the motor to power the train, it keeps everything running smoothly, and it can be an asset, or a hindrance. Laying track is more of a discussion than a demonstration. So this Article is more of a list of tips than a how to guide.

Well, there you have it, a run down on track laying. It really is a lot simpler than it sounds, so don't be discouraged. I almost forgot about one part, safety:

There are three methods that a person can use to lay track:

- Laying sectional track

- Laying flex track

- Hand laying track

Sectional track

Laying sectional track is the most popular method of laying track on a model railroad. Each piece is preformed, and can also have roadbed already attached to it. This makes installation easy, however, the trade off is that there a re a lot of joints in the rail.

Trains pick up electricity through the rails to power the motor. Joiners supplied with most sectional track do the trick to keep the electricity flowing to each section. However, there needs to be a better connection if the track is permanent. The solution is to solder the track together( see below). I would go a step further and add a wire jumper the bottom of each joint. This way, all the joints are properly connected, and will allow better operation of trains.

Soldering joints couldn't be easier. Unfortunately, soldering requires two hands, so I can't take pictures for reference. But I will describe the process as best I can:

Soldering joints couldn't be easier. Unfortunately, soldering requires two hands, so I can't take pictures for reference. But I will describe the process as best I can:

- Use an old toothbrush (or one not being used) to scrub the rail joints with rubbing alcohol. This washes away dirt, and shines the rails to make a better connection. If you can't get the track clean using this method, then don't use the piece of track as it is too far gone to be used. However, the piece can be saved for on the end of a spur where a locomotive will never need to travel.

- After the track joint is cleaned so that the track shines, apply a little bit of flux to the joint. The flux allows the solder to flow into the tiniest cracks with ease. Newer solder types can also have a rosin core which eliminates this step completely.

- During steps one and two, the soldering iron could have been plugged in so that it heats up in time for the soldering part. To apply the solder, the soldering iron needs to be heated so that the solder melts and flows into the joint. So do that now while pressing the iron against the track so it too heats up. The solder should flow into the joint and give off a very clean shine in a few seconds of contact.

- Let the joint cool for a few minutes. during this time the next joint could be prepared for soldering.

- Once the joint is cool, go to the center of the section and cut out the plastic attachment that holds the ties together. This is a piece of plastic that runs parallel to the metal rails and can be found between each pair of ties. If necessary, also pull off one or two ties on each side of the proposed solder joint. Repeat steps one through four to attach a wire to the track. This is called a 'feeder wire' which takes electricity from the main wires beneath the layout and connects them to the track.

If the track has roadbed already attached to it. the track can be attached straight to the table. It is preferred, however, to lay down a cork or foam roadbed between the track and the table top. The same goes for laying track in the other two methods mentioned above.

Flex track

Flex track is different in that YOU have to cut and shape where the track goes on the layout. This allows great freedom in what can be obtained in a model railroad. With flex track other details such as super-elevated curves, and easements. Flex track is also smoother, and more reliable than sectional track because it has fewer joints which must be soldered to allow electricity to flow.

When laying flex track, its best to start out on a straight section, then work into a curve, or a yard. When laying flex track in a curve:

Before any track laying commences, it is smart to lay roadbed so that you have a marked path for the trains.

|

| If needed, click to enlarge. |

- Start out at the start of the curve and solder the track leading into the curve to the straight section. Then shape the track to the curve you have marked out. As you shape the piece of track to the curve, spike the ties to the roadbed with a 1/2" nail. The track should stay centered on the roadbed as much as possible.

- When you get to the end of the section of track, the inside rail should extend farther than the outside rail. Keeping the track in the curve, cut out about two ties on the end of the track, then cut the track so that both sections are even, leaving about 1/2" of rail that is not supported by the cross ties.

- At this point, solder on the second section in the curve, and keep going forward until you are around the curve to another straight section.

- You can glue the track down, or leave the nails in place to keep the track steady. Also, you can add the extra ties back underneath the track to make it look smooth and complete.

Hand-laid track

Experienced modelers, and novices may sometimes hand lay their own track. it is pretty simple to do after some practice.

- Lay down the roadbed then lay out the cross ties on the roadbed. The ties can be glued down to keep them steady.

- Lay one rail, and spike it down every couple of ties. In smaller scales, you can buy spikes for the track, but in larger scales, I've found that 1/2" nails, or other small nails will work as well as spikes.

- Lay the next rail down, keeping it in gauge. Using an NMRA standards gauge for the scale you are modeling in works well for this. You can also use a wheel set, a railroad car, or just measure. On the second rail, the inside should be spiked first to make sure that the rail is in gauge, then spike the outside. Do this for every tie until the section is complete.

Switches

Switches, or turnouts, allow a train to change from one track to another. When laying turnouts, it's important to make sure that every joint is smooth, and cars can glide through them effortlessly. Switches can be powered by a motor underneath the table, or next to the switch. They can also be thrown back and forth by hand. If possible, invest in switches where every rail is powered so that shorter locomotives can run through them. If you are running nothing but six axle locomotives, then an insulated turnout is acceptable.

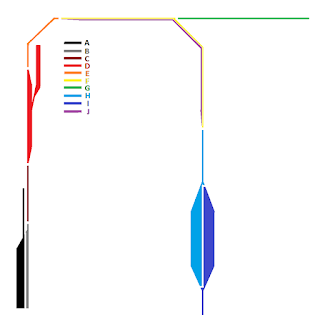

To wire a switch, Solder all joints. Insulated frogs are not powered, making wiring simple. The frog is the piece of track where the two inner rails cross each other and can make wiring different if the frog is powered. See below:

Bridges

A bridge is different because there is nothing but air under the track. When installing a bridge, make sure that the bridge is supported as well as possible, and is as level as can be. Though wires can't usually be feed to the middle of the bridge, in most cases a wire connection at each end will suffice. If a connection is needed, then run the wire up the backside of the bridge so it's not seen.

Wiring

On a simple oval, or starter set, the track is connected to the power pack in one place. We already went over powering a railroad, so here is the other end of it. The track must have a "feeder wire", that is a wire that connects to the track, and leads to a "bus" wire, which runs current to the whole layout. Sections can be wired so that multiple trains can run, or you can invest in a DCC system.

I personally believe that you should get DCC if you run more than two trains at once, and if you have a layout larger than about 10X10 feet. DCC is easier than wiring 12 different sections, I can tell you that right now.

For wiring, there are two common ways to wire a layout. The first is the "block control' method to wiring a layout. Before DCC, each train needed it's own line, or section of line to operate. Therefore, the layout was divided into divisions. In a way, this makes operating a railroad a little more realistic as in real life there are blocks for trains to operate in. However, this system makes for complicated wiring. An example is shown below:

DCC makes this wiring a lot simpler. Instead of having multiple blocks with on/off switches to control power to hte blocks like in the diagram above, the whole layout is under one or two blocks, and trains can run freely and independent of each other. Each locomotive has it's own decoder, a device that operates like a small computer. each decoder picks up electrical signals designed specifically for that decoder. The result is that each train engine can be told what to do, but only that particular engine will respond. It may sound complicated, but most of this process is automated. Also, the programming has been streamlined so that it is very simple.

Well, there you have it, a run down on track laying. It really is a lot simpler than it sounds, so don't be discouraged. I almost forgot about one part, safety:

- Always wear eye protection when cutting, sawing, or using utensils that could throw objects through the air.

- Occasionally, a dremel or a saw blade will be needed to make a cut. Always watch fingers and hands as the tools are sharp and can injure a person.

- Keep small children away from hazardous materials, however try to include them in anything that is not too hazardous.

- Wear ear protection when using loud tools.

- Always assume that a soldering iron is hot, and treat it accordingly.

- Use common sense and be careful.

No comments:

Post a Comment